Historie

Het duurzaamheid niveau

Met het gepatenteerde MDI/formaldehyde vrije plaatmateriaal heeft Singhboard Holding BV een economisch haalbaar alternatief ontwikkeld. De huidige houtenplaten die in gebruik zijn dragen 1,65 GJ/mᵌ bij aan de Global Warming Potential (GWP). Het alternatief dat door Singhboard Holding BV op de markt wordt gebracht heeft een negatieve (GWP). Met een jaar productie van 60.000 mᵌ plaatmateriaal, komt dit overeen met -364364 GJ. Uitgaande van een gemiddelde nieuwbouw prefabbeton woning (20 mᶾ plaatmateriaal) is de productie geschikt voor 3000 woningen. Voor houtskeletbouw woningen zelfs voor 500 woningen. De oprichting van onze fabriek in Noord-Nederland zal tegelijkertijd bijdragen aan het voorkomen van leegloop en biedt werk aan ongeveer 57 mensen (direct in dienst), waarvan circa 32 ongeschoolde arbeidskrachten.

Dit in overeenstemming met de principes van duurzaamheid, maatschappelijk verantwoord ondernemen (MVO) en de groene economie. Wat in overeenstemming is met de economische en duurzame ambities van de Nederlandse overheid en met haar aanverwante mondiale overeenkomsten.

Van onderzoek naar idee

Het ontwikkelen van een nieuw product is in het algemeen gebaseerd op wetenschappelijk onderzoek, en duurt enige tijd om de theorie in praktijk om te zetten. De basis van het idee van Singhboard Holding BV is dan ook wetenschappelijk onderzoek. In de periode 2005 – 2007 heeft de initiatiefnemer een casestudy in het district Nickerie in de Republiek Suriname uitgevoerd. Zijn onderzoek heeft geleid tot een wetenschappelijk model om het begrip duurzaamheid te visualiseren. Tijdens deze studie constateerde hij dat de vezelrijke rijststro werd verbrand door de rijstboeren. Dit had belangrijke gevolgen voor de gezondheid, met name voor de omwonenden van de rijstvelden. Vanuit dit gegeven werd de zoektocht gestart naar het praktische gebruik en de toepasbaarheid van vezelrijke plantenresten afkomstig van de landbouw. Dit leidde uiteindelijk tot een duurzaam plaatmateriaal, bestaande uit vezelrijke plantenresten en een gezondheid-/ milieuvriendelijke bindmiddel.

Van idee tot het ontwerp

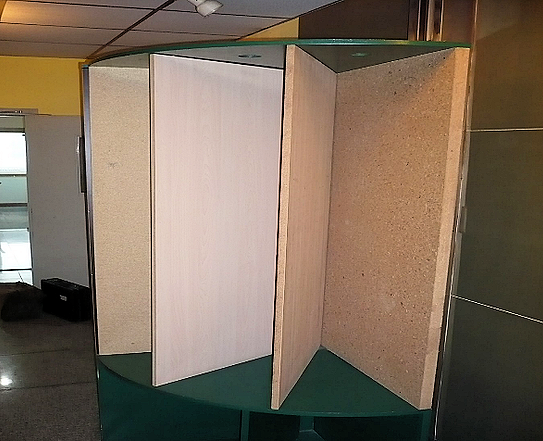

Het gepatenteerde plaatmateriaal is uniek voor de EU en heeft tenminste dezelfde kenmerken als de in gebruik zijnde huidige reguliere houtenplaten. Daarnaast is het productieproces ontwikkeld en ontworpen, in overeenstemming met het duurzaamheidsconcept. Daarbij heeft Singhboard Holding BV het voordeel en de nodige juridische rechten dat er geen andere onderneming dit product, of een gelijkwaardig product of proces op de markt kan brengen. Informatie met betrekking tot het productieproces en producten wordt om deze reden alleen verstrekt onder strikte geheimhouding. Om Octrooi (lees:patent) te verkrijgen is er in eerste instantie een onderzoekadvies verkregen van het Octrooibureau om te zoeken naar eventuele bestaande/toegekende octrooien. Na deze fase werd de uitvinding gedeponeerd als zijnde een uitvinding. Na het ontvangen van het nieuwheidsonderzoek rapport is vervolgens de uitvinding aangescherpt. Uiteindelijk is het Octrooi verkregen en ingeschreven in het Octrooiregister.

Van ontwerp tot functioneel gebruik

Net als andere houten plaatmateriaal, is de MDI-/formaldehyde vrije Singhboard Duurzaam plaatmateriaal (SIBODU), onderworpen aan technische mechanische eigenschappen en kenmerken. Deze eigenschappen zijn belangrijk voor het bepalen van de functionaliteit. Singhboard heeft daartoe een eigen onderzoek- en testlaboratorium opgezet om klanten een totaaloplossing te kunnen bieden. De mechanische eigenschappen kunnen worden verdeeld in:

-

Treksterkte

-

Druksterkte

-

Splijtkracht

-

Buigsterkte

-

Slijtkracht

Het plaatmateriaal van Singhboard Holding BV kan zodanig worden geproduceerd, dat de elasticiteitsmodulus kan worden aangepast aan de specifieke eisen van de klant en voldoend vervolgens aan de ISO normen NEN 6700, NEN 6702 en NEN 6760. Daardoor is het mogelijk om plaatmateriaal te leveren met verschillende gewenste buig- en druksterkte (elasticiteitsmodulus). Het plaatmateriaal kan dus voor diverse toepassingen worden gebruikt. Bovendien is het mogelijk de brandwerendheid en vochtbestendigheid van het plaatmateriaal van Singhboard Holding BV te verhogen. Dit is afhankelijk van de omgeving waar het plaatmateriaal wordt toegepast, en is te onderscheiden in:

-

Natte of droge ruimte

-

Bouwconstructies of decoratieve toepassingen

-

Gebruiksfuncties (woning, kantoor, school, fabriek, etc.)

Het plaatmateriaal van Singhboard is geschikt voor buiten- en architecturale inrichting en kan worden gebruikt als decoratieve- of als afwerkings materiaal, zoals dak-, vloer- en draagconstructies. De meest gebruikte dikte van het plaatmateriaal voor deze constructies is 18 mm.